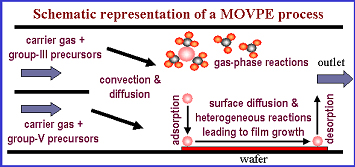

Introduction of simulation and modeling into

development of MOVPE technology becomes more and more intensive in the last years. Modeling

may be used for both process and reactor optimization purposes. Besides the description

of transport phenomena (flow, heat, species), an adequate chemistry model is necessary to predict

deposition rates and uniformities and layer compositions. A surface chemistry model should be

able to predict epitaxial growth on the wafer as well as parasitic deposition on the reactor

inner surfaces, which occurs under kinetically limited conditions.

|

We developed an integrated approach to simulation of III-V materials growth by MOVPE.

The low temperature kinetic effects are described using a general mechanism – the blocking

of group III species adsorption sites by methyl radicals. The mechanism is based on experimental

data on the decomposition of group III metal-organic precursors on III-V semiconductor surfaces.

Deposition at intermediate temperatures that occurs under mass-transport limited growth

conditions necessitates detailed modeling of transport processes accounting for reactor

geometry features. These conditions are characteristic for MOVPE of group III arsenides

and phosphides and the modeling results for these materials can be found in the reference list.

Another advantage of the formulated model is its ability to predict the growth rate and

composition of the epitaxial layers under the conditions when the desorption of species from

the surface is the rate limiting process. This is particularly important for the regimes

of thin strained quantum well growth. The developed models describe growth of the epilayers

in the Al-Ga-In-As-P system used for growing heterostructures for light emitting diodes,

solar cells, laser diodes, high-electron mobility transistors, hetero-bipolar transistors

and vertical cavity surface emitting lasers. These structures include GaAs, InP, AlGaAs,

InGaAs, and InGaP layers.

References on Models and mechanisms

2001

On low temperature kinetic effects in Metal - Organic Vapor Phase Epitaxy of III-V compounds.

R.A. Talalaev, E.V. Yakovlev, S.Yu. Karpov, Yu.N. Makarov.

Journal of Crystal Growth, Vol.230, p.232-238, (2001).

2000

Quasi-thermodynamic models of surface chemistry: application to MOVPE of III-V ternary compounds.

S.Yu. Karpov, E.V. Yakovlev, R.A. Talalaev, Yu.A. Shpolyanskiy, Yu.N. Makarov, S.A. Lowry.

Electrochemical Society Proceedings, Vol. 2000-13, p.723-730, (2000).

1997

Advanced mathematical models for simulation of radiative heat transfer in CVD reactors.

F.Durst, L.Kadinski, Yu.N.Makarov, M.Schafer, M.G.Vasil’ev, V.S.Yuferev.

Journal of Crystal Growth, Vol.172, p.385-395.

1995

Development of advanced mathematical models for numerical calculations of radiative heat transfer in metalorganic chemical vapour deposition reactors.

L.Kadinski, Yu.N.Makarov, M.Schafer, M.G.Vasil’ev, V.S.Yuferev.

Journal of Crystal Growth, Vol.146, p.209-213, (1995).

References on III-V growth in the Horizontal and Planetary Reactors

2003

Advances in the modeling of MOVPE processes.

S. Yu. Karpov.

J. Crystal Growth, Vol.248, p.1-7, (2003).

2001

Detailed modeling of Metal Organic Vapor Phase Epitaxy of III-V ternary compounds in production-scale AIX 2400G3 Planetary Reactor.

E.V. Yakovlev, Y.A. Shpolyanskiy, R.A. Talalaev, S.Y. Karpov, Y.N. Makarov, T. Bergunde, and S.A. Lowry.

Electrochemical Society Proceedings, Vol. 2001-13, p.292-300,(2001).

2000

Comprehensive reactor-scale modeling of III-V ternary compound growth by MOVPE.

E.V. Yakovlev, R.A. Talalaev, S.Yu. Karpov, Yu.A. Shpolyanskiy, Yu.N. Makarov, S.A. Lowry.

Mat. Res. Soc. Symp. Proc., Vol.616, p.153-158, (2000).

Modeling and experimental verification of transport and deposition behavior during MOVPE of Ga1-xInxP in the Planetary Reactor.

M. Dauelsberg, L. Kadinski , Yu.N. Makarov , T. Bergunde , G. Strauch, M. Weyers.

Journal of Crystal Growth, Vol.208, p.85-92, (2000).

1997

Heat transfer and mass transport in multiwafer MOVPE reactor: modelling and experimental studies.

T.Bergunde, M.Dauelsberg, L.Kadinski, Yu.N.Makarov, M.Weyers, D.Schmitz, G.Strauch.

Journal of Crystal Growth, Vol. 170, p.66-71, (1997).

Process optimisation of MOVPE growth by numerical modelling of transport phenomena including thermal radiation.

T.Bergunde, M.Dauelsberg, L.Kadinski, Yu.N.Makarov, V.S.Yuferev, D.Schmitz, G.Strauch, H.Jurgensen.

Journal of Crystal Growth, Vol.180, p.660-669, (1997).

Modelling and process optimization in a radial flow multiwafer MOVPE reactor.

T.Bergunde, M.Dauelsberg, L.Kadinski, Yu.N.Makarov, G.Strauch, H.Jurgensen.

Society Proceedings, Vol. 97-25, p.230-237, (1997).

1995

Transport and reaction behaviour in Aix-2000 Planetary MOVPE reactor.

T.Bergunde, D.Gutsche, L.Kadinski, Yu.Makarov, and M.Weyers.

Journal of Crystal Growth, Vol.146, p.564-569, (1995).

Algorithms and Models for Simulation of MOCVD of III-V Layers in the Planetary Reactor.

T.Bergunde, M.Dauelsberg, Yu.Egorov, L.Kadinski, Yu.N.Makarov, M.Schafer, G.Strauch, M.Weyers.

Simulation of Semiconductor Devices and Processes, Vol.6, edited by H.Ryssel, P.Pichler, p.328-331, (1995).

1994

Modelling of growth in a 5x3 inch multiwafer metalorganic vapour phase epitaxy reactor.

T.Bergunde, M.Dauelsberg, Yu.Egorov, L.Kadinski, Yu.N.Makarov, M.Schafer, G.Strauch, M.Weyers.

Journal of Crystal Growth, Vol. 145, p.630-635, (1994).