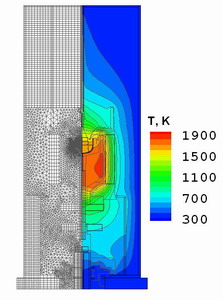

Fig. 1.

The combined computational grid for the global heat computations

in the furnace and temperature distribution.

|

Cz growth of the SiGe crystals

Using CGSim software, the Cz growth of the Si1-xGex

crystal with 3 at%

initial melt Ge content was considered [1]. An important distinction of

the Si1-xGex growth is that the germanium concentration changes in the melt

and the crystal due to the segregation. This phenomenon is accounted for in

the computations, so that the physical properties vary with the crystal

height.

The combined computational grid of approximately 15000 finite volumes

(FVs) for the global heat computations and temperature distribution

in the furnace is presented in Fig.1. Here, the difference between

isotherms is 100 K, and the maximum temperature is about 1850 K. The

temperature of the outer wall was assumed to equal to 300 K. The power

of the heater was slightly adjusted to provide the desired crystallization

rate.

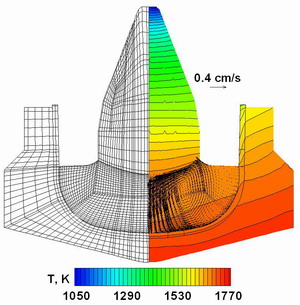

Fig. 2.

The grid for the crystallization zone (left),the temperature distribution

and the averaged melt flow pattern obtained by the 2D computations (right).

|

Detailed analysis of the crystallization zone

has been made within the Reynolds averaging approach (2D computations)

and 3D unsteady computations. The two-dimensional computation considers

turbulent mixing using the Chien turbulence model. The computational

grid for the crystallization zone (left), temperature distribution and

the averaged melt flow pattern (right) are presented in Fig.2. One can

see that 2D approach predicts an active downward motion along the axis

of symmetry.

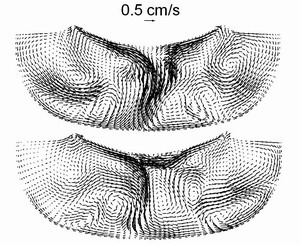

However, the real melt flow is three-dimensional

and unsteady; so, only 3D computations can provide comprehensive

information about the unsteady flow behavior and heat mixing in the

melt. The computational grid for 3D computations contains about

150000 FVs (Fig.4). Examples of the instantaneous flow patterns

obtained by the 3D computation are presented in Fig.5. One can see

that the melt flow has a complex structure. The highest melt velocity

at the center is about 1 cm/s, the characteristic velocity on the

melt periphery is about 1mm/s.

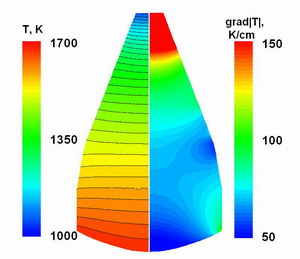

Fig. 3.

The distributions of the temperature(left) and the temperature gradient

(right) in the crystal.

|

Fig. 4.

The computational grid for 3D computations contains about 150000 FVs.

|

Fig. 5.

Examples of the instantaneous flow patterns obtained by the 3D computation.

|

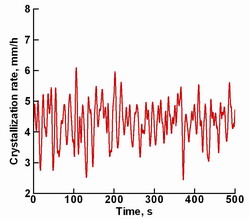

It is interesting that the crystallization rate averaged over

the crystallization front fluctuates because of melt turbulent pulsations,

which affects growth stability. The fluctuations were numerically found

to have the amplitude of about 1.2 mm/h. This result can be obtained

only in 3D unsteady computations and explained the fact that a stable

crystal growth is possible for this growth system only if the averaged

pulling rate is higher than 1 mm/h.

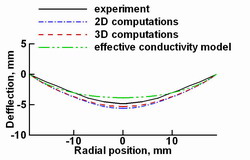

An important parameter of bulk crystal growth is the geometry of

the crystallization front, which influences the defect formation and

impurity incorporation. The front geometry is sensitive to any changes

in the system and can be used as a criterion of simulation adequacy.

The crystallization front geometry is computed by the 3D and 2D approaches

accounting for the melt flow. Besides, the effective conductivity model,

which neglects melt convection effect, has also been used for the

melt-crystal interface geometry computations. The conductivity model

provides a smaller front deflection than the 2D and 3D flow models and

has a lager disagreement with the experimental shape. One can see that

the interface obtained in the 3D simulation is closer to the experimental

data than that provided by the 2D approach. So, the melt flow consideration

yields a more accurate description of the physical processes in the system

and gives an adequate crystallization front geometry.

Fig. 6.

The fluctuations of the crystallization rate averaged over the

crystallization front.

|

Fig. 7.

The computed and experimental crystallization front shapes.

|

References

[1] O.V. Smirnova, V.V. Kalaev, Yu.N. Makarov, N.V. Abrosimov,

H. Riemann, J. Crystal Growth 266 (2004) 74-80.

|